The Role of EVA in Slipper Production: Features, Benefits, and Applications

what will you read...

What is EVA?Benefits of EVA in Slipper Production1. Lightweight2. High Comfort and Flexibility3. Water Resistance4. High Durability and Wear Resistance5. Slip Resistance and Safety6. Versatility in Design and Color OptionsComparison of EVA with Other Common Materials in Slipper ProductionApplications of EVA in the Slipper IndustryConclusion

In the footwear and slipper industry, the use of high-quality raw materials directly impacts the comfort and durability of the product. One of the most widely used materials in slipper manufacturing is EVA (Ethylene Vinyl Acetate), which is an ideal choice for manufacturers due to its lightness, flexibility, and durability. In this article, we will explore EVA, its benefits in slipper production, and how it compares to other materials.

What is EVA?

EVA is a type of polymer composed of ethylene and vinyl acetate. The amount of vinyl acetate in the composition determines the properties of the material. The higher the percentage of vinyl acetate, the softer and more flexible the EVA becomes. Due to its unique physical and mechanical properties, EVA is widely used in the production of various footwear, slippers, and even sports equipment.

Benefits of EVA in Slipper Production

1. Lightweight

One of the key features of EVA is its low weight. Slippers made from this material do not put pressure on the feet, making walking more comfortable.

2. High Comfort and Flexibility

EVA has excellent flexibility, allowing it to adapt well to foot movements while walking. Additionally, it acts as a shock absorber, reducing the impact on the feet.

3. Water Resistance

Since EVA does not absorb water, slippers made from this material perform exceptionally well in humid environments such as bathrooms, pools, and beaches.

4. High Durability and Wear Resistance

EVA slippers are highly durable and last longer than many slippers made from other materials. They are resistant to wear and tear, ensuring prolonged use.

5. Slip Resistance and Safety

The surface of EVA is designed to create high friction, which helps reduce the risk of slipping. This makes EVA slippers a safer choice for wet and slippery surfaces.

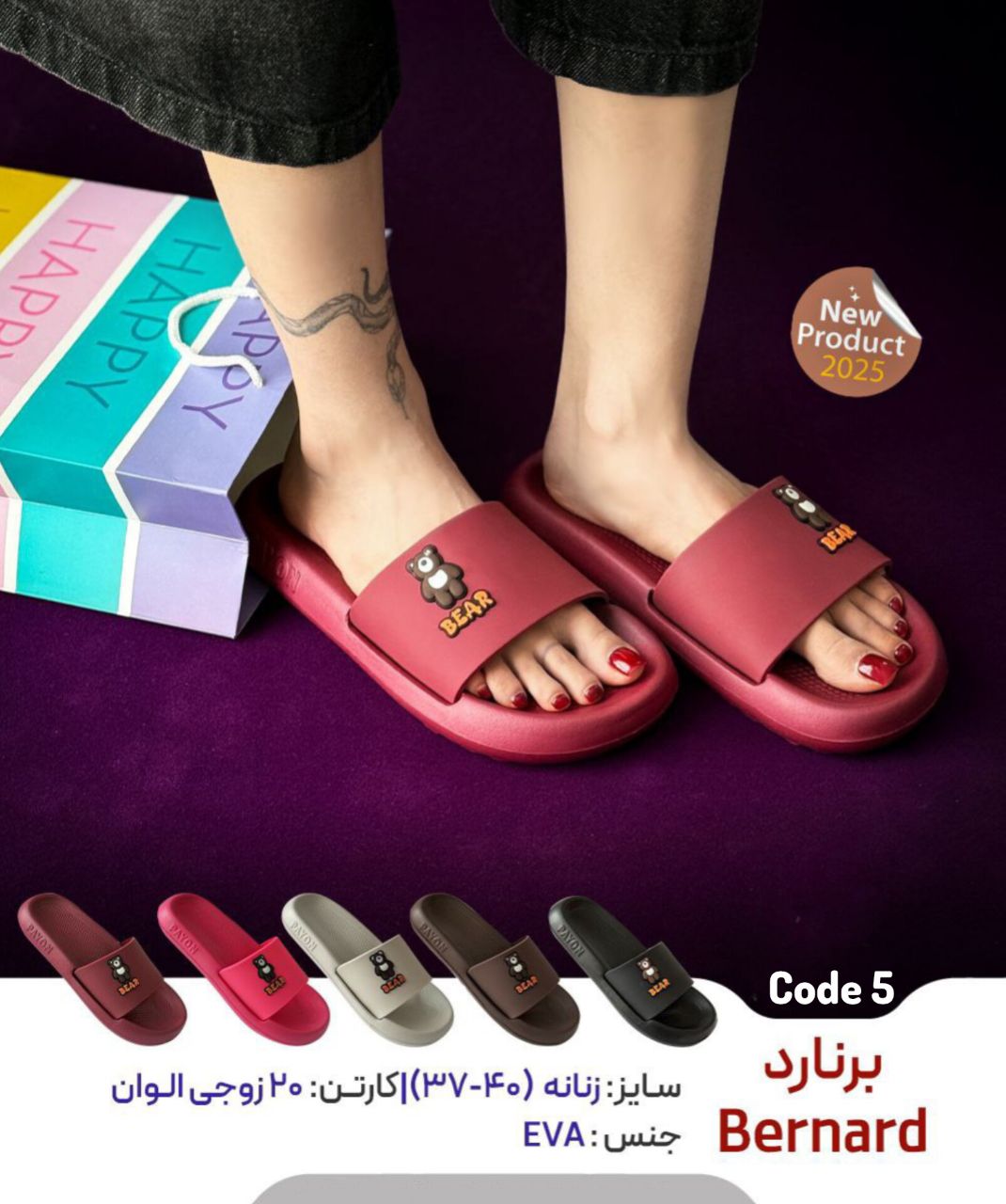

6. Versatility in Design and Color Options

EVA is easy to mold, allowing manufacturers to produce slippers in various designs and attractive colors. It also enables the printing of stylish and fun patterns on slippers.

Comparison of EVA with Other Common Materials in Slipper Production

– EVA vs. PVC: PVC slippers are usually harder and heavier, whereas EVA offers more flexibility and softness.

– EVA vs. Rubber: Rubber is more durable but also heavier and may cause foot sweating. EVA provides a balance of softness and lightness for better comfort.

– EVA vs. PU (Polyurethane): PU is another strong and comfortable material, but its production cost is higher compared to EVA.

Applications of EVA in the Slipper Industry

EVA is widely used in the manufacturing of various types of slippers, including:

– Pool and Bath Slippers: Due to their waterproof properties and resistance to moisture.

– Casual and Everyday Slippers: Because of their lightweight and softness.

– Medical and Orthopedic Slippers: To reduce foot pressure and absorb impact while walking.

– Children’s Slippers: Due to their flexibility and lightweight design.

Conclusion

With features such as lightweight construction, flexibility, comfort, water resistance, and long-lasting durability, EVA has become one of the best raw materials for slipper production. This material not only provides enhanced comfort for users but also allows manufacturers to create a variety of stylish and functional designs. If you are looking for durable and comfortable slippers, those made from EVA are an excellent choice.